Calibrate Imaging System for Dimension Metrology

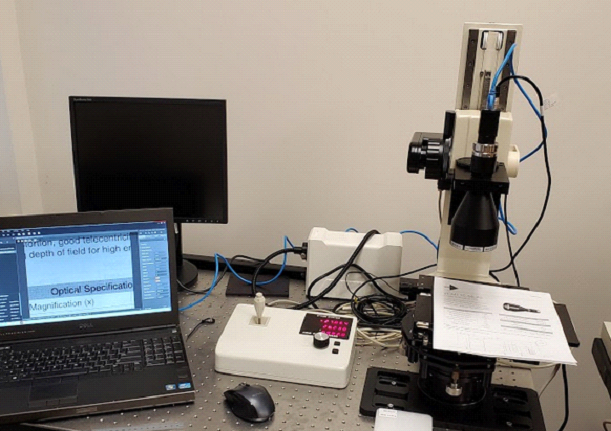

A setup like this one is commonly used to measure the hole or its location using front lighting. The precision for measuring the diameter and the distance is not the same. This article will attempt to help you make this decision.

Setup

Dot calibration target. The dimension has 0.001mm accuracy.

Measured location error (center of dot). Unit 1%. Error source for distance measurement: imaging system distortion + target error.

Measured diameter error (to the mean diameter). Unit 1%. Error source for diameter measurement: lighting + edge detection algorithm + imaging system uniformity + target error.

As you can see, the measurement of center location has much less error while the measurement of diameter has more types of error. The lighting and edge detection error typically depend on the edge's sign (from light to dark or dark to light). There is an optimized exposure range for diameter measurement.

Picture below showing the relation of calibrated pixel size vs exposure. As you can see the resolution through dot center distance is consistent while through dot diameter is affected by the exposure and algorithm. You can calibrate out the diameter error when the exposure is fixed.

This particular telecentric lens has excellent linearity, with distortion of less than 0.1%. Suppose the user can calibrate the lighting and edge effect, the measurement of both diameter and location can achieve 0.001*L precision, which translates into 0.5mm +/-0.0005mm for diameter and 1mm +/-0.001mm for the dot distance. The pixel resolution is 0.010371mm.

With such a low distortion telecentric lens, some low order error in image distortion will be noticeable. It can either be from the lens system or the target itself. In this case, it is most likely lens system manufacturing error. It is possible to compensate for this low order error with self-calibration. This low order error compensation is more important for the imaging system that doesn’t use the telecentric lens.

PME is a one-stop supplier of image-based measurement. We offer consulting, standard and customized telecentric lens, LED light, calibration target, and application software. Please feel free to contact kai@kai-eng.com for your metrology and machine vision needs.